About Formwork:

Building a country needs a build to create a solution, and companies like Cassaform are moving in that direction from a long time ago. They are looking forward to hiring and sales for shoring, propping, and formwork. All of the major companies in the race have set the bars high for providing quality and cost-effective service to the clients. The prime focus is on delivering smart and innovative formwork solutions by delivering quality products throughout the globe, including a worldwide client base in the USA, Europe, and the Middle East. Cassaform Australia has strong partners in the industry who walk hand in hand for the Growth of the company and getting innovative sources. The teamwork at a different end, which provides formwork services, shows the true spirit and hunger for development.

Propping, Shoring, and Formwork:

An organization that is looking forward to providing a strong supply chain for propping, shoring, and formwork deals in the multi-operation of the products throughout the serving area. The Growth in specific area coincides with quality formwork equipment. Difference is purely committed to providing high-end solutions and equipment to our clients. Our services are cost-effective and customer friendly. We hire and sales for all types of residential and commercial customers. Our market-leading and tailored solutions enable our client for healthy engineering practice with an expert team for sharing technical reviews regarding formwork. The highest safety standard tests the manufacturing and designing techniques. Companies like Cassaform organize their portfolio, keeping in view the safety of the team with comprehensive hard work.

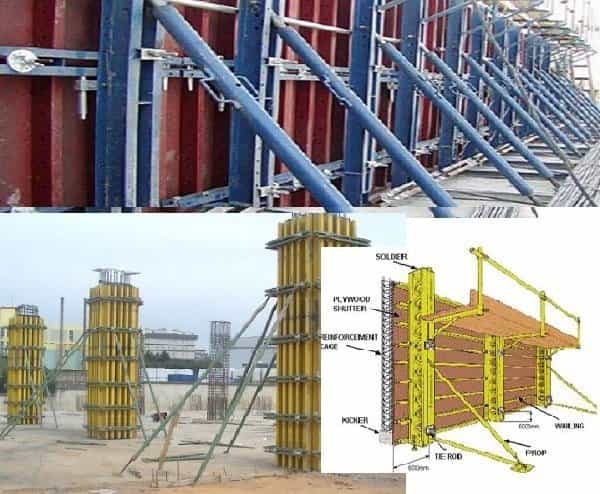

Formwork:

High end designing and support for formwork sets a tone for the modular system. Formwork easily integrates into any type of construction sample and its testing for a particular fabrication. It used for a temporary mold and traditional concrete pillars. Formwork is constructed or formed by the arrangement of timber, plastic, steel, or glass fiber by pouring the concrete. Reinforced plastics and glass plays a very important role as a side agent while pouring the concrete in the absence of specified material. It could be done either in a permanent solution or for preparing a temporary base. The formwork is also known as the shuttering of the concrete. In this method, the stuffy material fills a gap with a rigid liquid concrete for providing additional support to the structure. The complete structure takes time, and about 20-25 % of the total cost of the structure relies on this.

Here are some of the types of formwork:

- Plywood: it is the most commonly used material for the formwork of all leads. It is very easy to store and handle as they are lightweight hence improving the overall efficiency.

- Steel: these are not one of the lightest but one of the strongest in the market. As steel does not absorb any concrete material, so they avoid getting shrink and wrap.

- Plastic: Glass and vacuum plastics are the main components of these types of formwork. They also do not absorb any kind of moisture from concrete.

- Aluminum: They add up in the prefabrication of the network. They are lightweight, so again, aluminum is highly preferable for formwork structuring.